MAHWAH, NJ—Metropolitan Car-o-liner, the first and a top-selling distributor of Car-O-Liner equipment in North America, has launched a new streamlined website featuring a clean and vivid modern design that greatly improves navigation and the overall user experience.

For more than forty years, Metropolitan Car-o-liner has supplied the automotive after-market with innovative solutions, technical development, training, and customer support. The new website, and sharply designed logo, brings the brand together and is more representative of the company’s market position.

“As the leading global provider of high-quality, technologically-advanced collision repair equipment to the automotive aftermarket, Car-o-liner has a responsibility to our customers to keep our e-commerce website as easy to use as possible” states Dave Demarest Jr., President of Metropolitan Car-o-liner. “Today, customers will find the website content better organized, easier to navigate and displayed properly on any device they are using.”

The repair needs of the auto body shop are continuously and rapidly changing which is why Car-o-liner offers a wide variety of flexible solutions for repairs that range from minor to structural. “Everyone at Car-o-liner takes pride in our customer service. This new website not only enhances our e-commerce but builds on our reputation for great service as well” says Demarest.

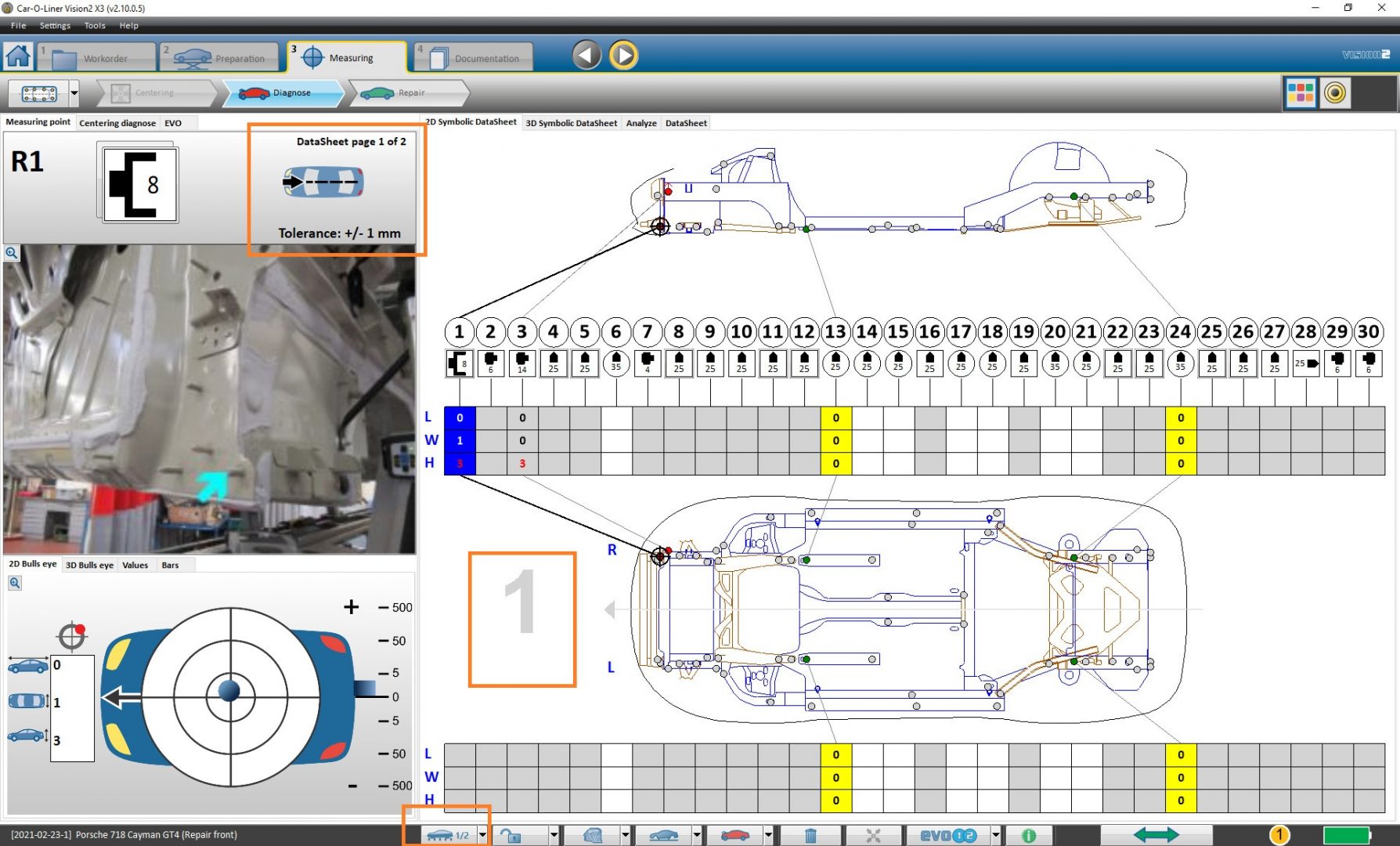

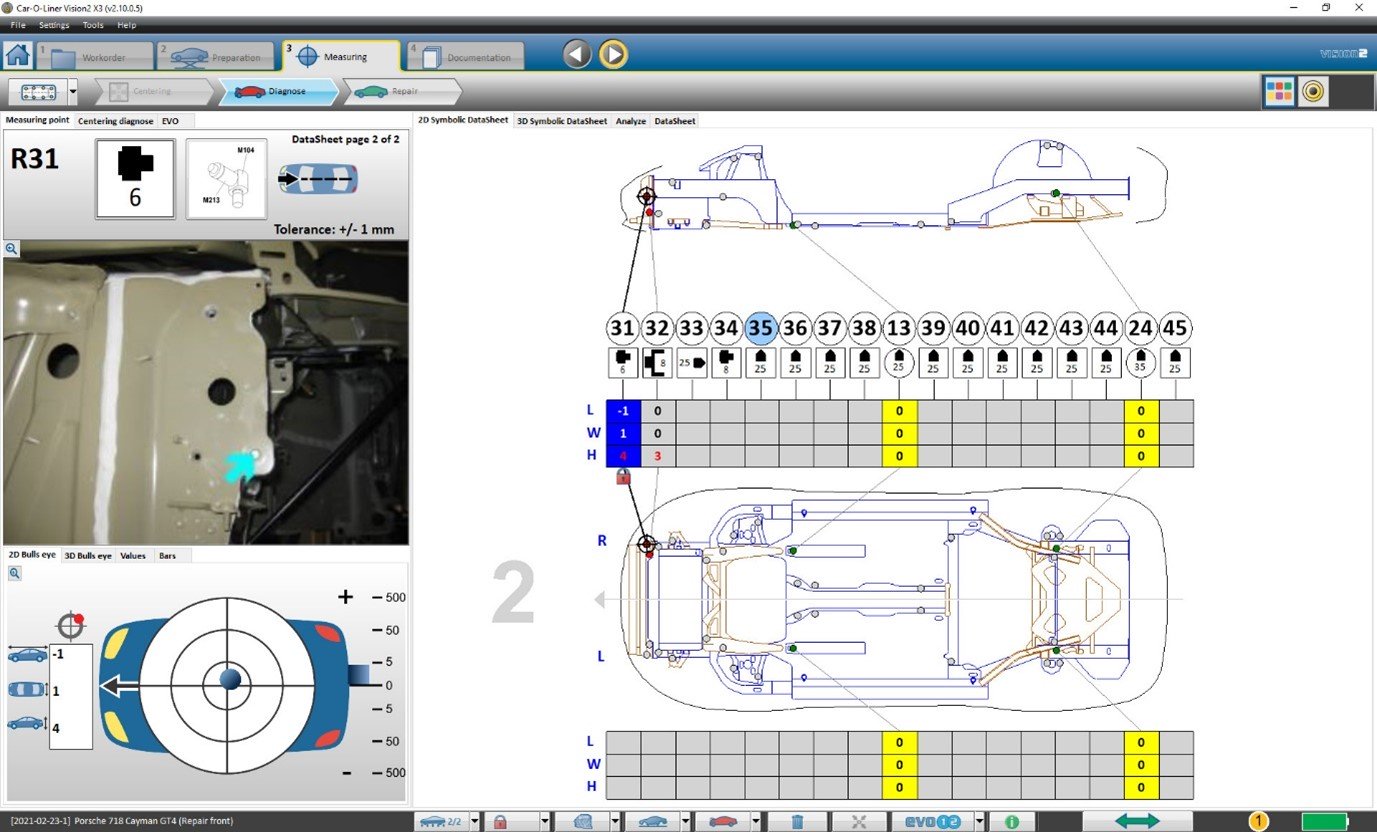

Car-o-liner products include Frame Equipment, Measuring Systems, Holding/Fixturing, Joining Systems, Workshop Solutions and Aluminum Repair Solutions. Training is available for all products so every shop team member can use Car-o-liner equipment effectively and efficiently from day one.